The spray nozzle is one of the most important equipment in the aerial application work. Despite its small cost and size in relation to the aircraft, it determines the main characteristics of the job, such as the flow rate, the correct coverage and the deposition of the product in the target where it is desired. That is, the small tool is decisive in the final result of the application and, in the event of a failure in its operation, it can jeopardize the entire investment made by the ag aviation operator.

Conducting research is a responsibility of technology manufacturers. Investigations, both in the field and in the laboratory, are very important to assess the performance of products, ensure that they are being manufactured regularly, obtain data to help users, observe areas for improvement and, above all, guarantee safety and efficiency in the aerial application.

In the case of rotary atomizers, which are equipment developed for low-volume applications, the responsibility of manufacturers is even greater. This type of work is more sensitive, requiring special care and almost perfect calibration, in order to combine maximum efficiency with the highest safety standards.

Zanoni Equipamentos, since the beginning of our work in the manufacture of rotary atomizers, has constantly invested in research and dialogue with the greatest specialists in the subject. In addition to the intense work in the field carried out in Brazil, aimed at understanding the performance of our rotary atomizers for the protection of the most diverse crops, the company has also been investing in the analysis of the performance of the equipment in other special works besides row crops, such as forest protection and public health. Our research program has two main goals:

From our partnership with Sabri (agronomist consulting firm), from some projects done with the Pesticide Application Technology Laboratory (PAT-LAB) at the University of Nebraska and from the feedback of operators, we have been able to assess:

The use of rotary atomizers for ag operations dates back to the 1950s, when the French began using low-volume applications (10L/ha - 1 GPA) to control the Sigatoka disease in banana plantations in Africa. In the following decade, the US Department of Agriculture (USDA) developed a program for the application of Malathion in low volume, to control boll weevil in cotton plantations in the south of that country, increasing the popularity of this type of technology. Still in the 1960s, Brazil carried out the first tests with low-volume aerial application and, in the following decade, the first rotary atomizers were introduced in the country. A few years later, in some parts of the world, the use of oil began to become popular in the ag aviation industry, improving the efficiency of low-volume application work. This technology, now known as Low-Volume in Oil (BVO), was introduced in Brazil in 2000, exponentially increasing the use of rotary atomizers by the local 2500 ag aircrafts (for more information, see the article Low Volume Revolution, published in the AgAir Update magazine).

| Type of Nozzle | Flow Rate | Average Target Coverage |

| Flat Fan | 3 GPA | 3% – 5%* |

| Zanoni Atomizer | 2 GPA | > 5%** |

| Zanoni Atomizer | 1 GPA | 3% – 5%** |

| Flat Fan | 2 GPA | 1% – 3%* |

| Zanoni Atomizer | 0.5 GPA | 1% – 3%** |

* Data taken from field research carried out in the US and Brazil with different types of flat fan spray nozzles on different agricultural turboprop aircrat.

** Data collected in dozens of field research carried out with different Zanoni atomizers on different agricultural turboprop aircraft.

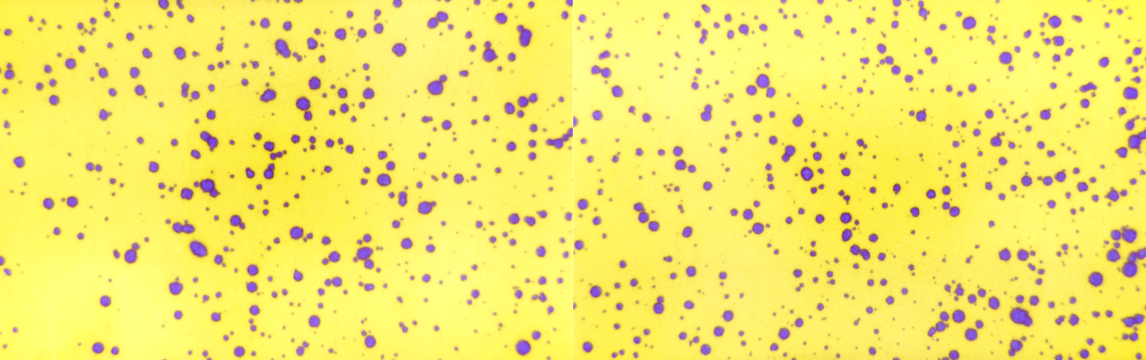

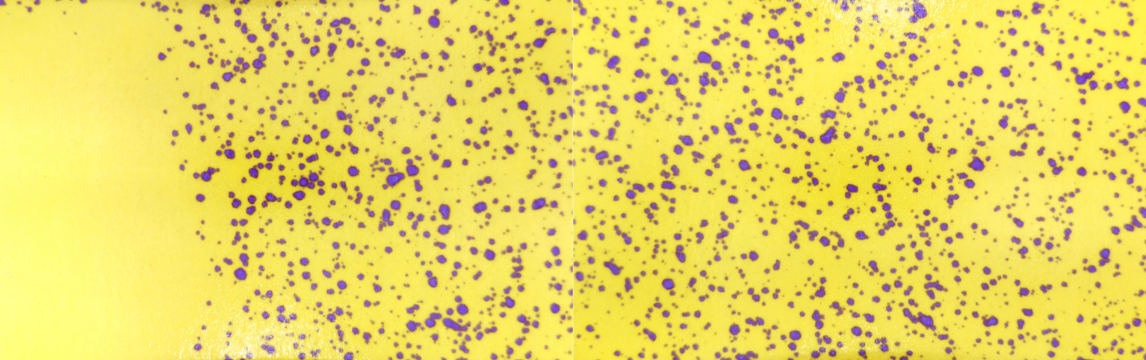

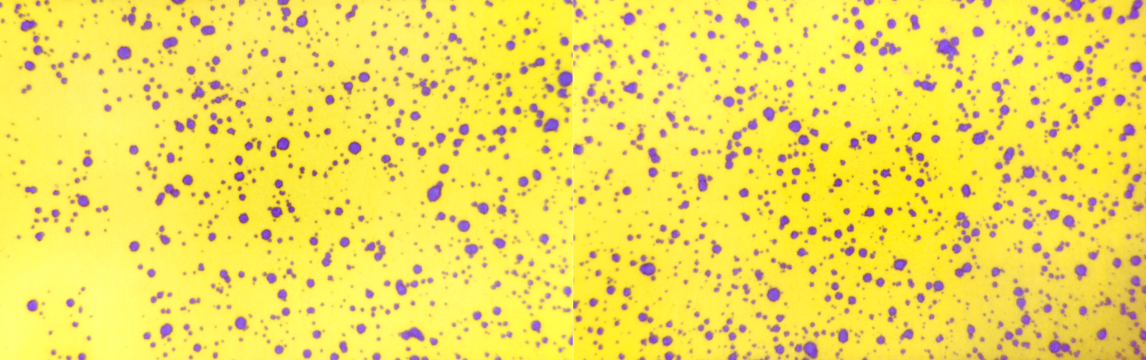

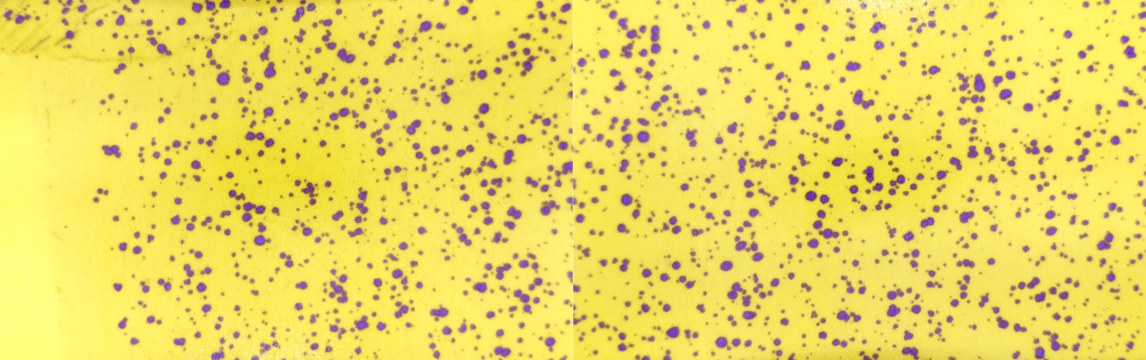

| AIR TRACTOR AT 502 (2 GPA) | AIR TRACTOR AT 402 (1 GPA) | AIR TRACTOR AT 502 (1 GPA) | EMBRAER IPANEMA 202 (1.5 GPA) |

|

|

|

|

|

|

|

|

| Nozzle | Deposition in middle canopy (ml/m²) | Deposition in lower canopy (ml/m²) | Total deposition (ml/m²) | |

| Insecticide | Atomizer | 0,717 | 0,662 | 1,937 |

| Flat Fan | 0,619 | 0,560 | 1,662 | |

| Superiority | 16% | 18% | 16% | |

| Insecticide + Adjuvant 1 |

Atomizer | 0,843 | 0,817 | 2,244 |

| Flat Fan | 0,666 | 0,597 | 1,763 | |

| Superiority | 26% | 37% | 27% | |

| Insecticide + Adjuvant 2 |

Atomizer | 0,969 | 0,891 | 2,576 |

| Flat Fan | 0,741 | 0,695 | 1,974 | |

| Superiority | 30% | 28% | 30% | |

| Insecticide + Adjuvant 3 |

Atomizer | 0,971 | 0,811 | 2,529 |

| Flat Fan | 0,762 | 0,680 | 1,982 | |

| Superiority | 27% | 20% | 27% |

*Field research comparing AT402 with rotary atomizer applying 1 GPA and with hydraulic nozzle applying 1.5 GPA in corn crops.

| Nozzle | Flow Rate | Deposition at 250m (ml/m²) | Deposition at 500m (ml/m²) |

| Atomizer | 1 GPA | 0,02 | 0,015 |

| Flat Fan | 3 GPA | 0,2 | 0,15 |

*Field research comparing rotary atomizer applying 1 GPA and hydraulic nozzle applying 3 GPA with 8 different product.

| Nozzle | DV01 | Relative Span | |

| Insecticide | Atomizer | 115 μm | 0,82 |

| Flat Fan | 104 μm | 1,12 | |

| Superiority | 10% | 27% | |

| Insecticide + Adjuvant 1 |

Atomizer | 104 μm | 0,69 |

| Flat Fan | 83μm | 0,84 | |

| Superiority | 25% | 18% | |

| Insecticide + Adjuvant 2 |

Atomizer | 114 μm | 0,63 |

| Flat Fan | 99 μm | 0,95 | |

| Superiority | 15% | 34% | |

| Insecticide + Adjuvant 3 |

Atomizer | 125μm | 0,62 |

| Flat Fan | 104μm | 0,81 | |

| Superiority | 20% | 24% |

*Field research comparing AT402 with rotary atomizer applying 1 GPA and with hydraulic nozzle applying 1.5 GPA.

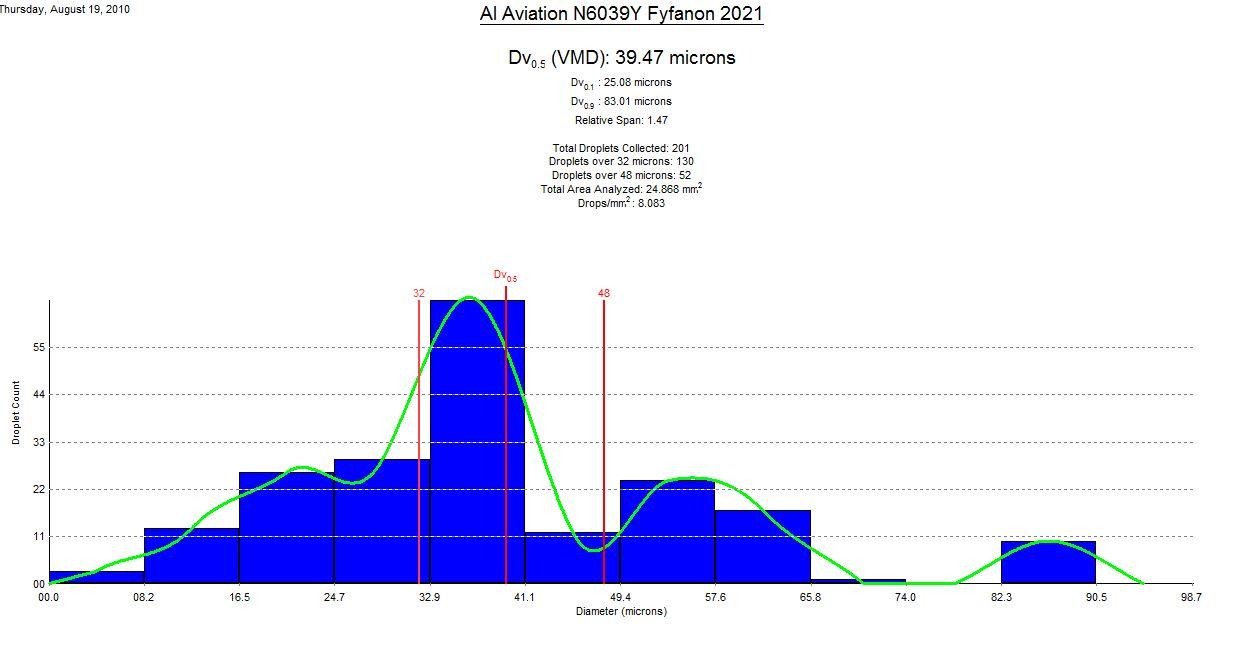

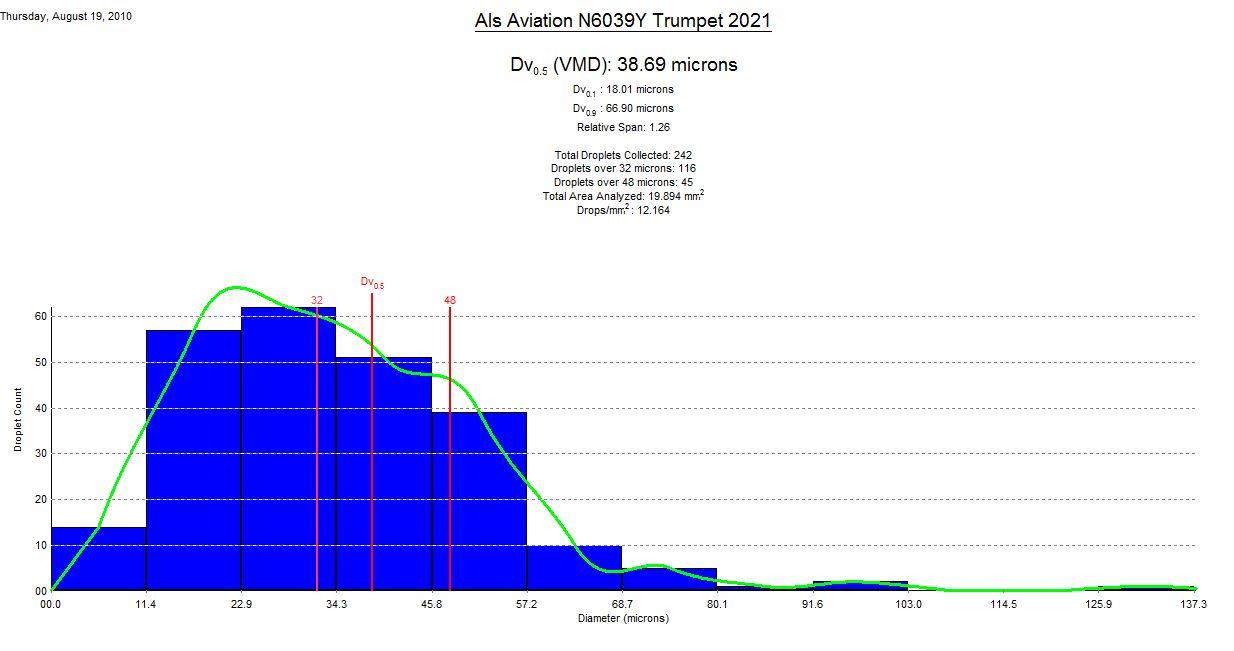

Wind tunnel tests performed at the Pesticide Application Technology Laboratory (University of Nebraska-Lincoln) demonstrated the suitability of the Zanoni atomizer for application of Foray 76B.

The tests, funded by our distributors at Turbine Conversions, were run in the University of Nebraska wind tunnel on January 13, 2021, evaluating the performance of the Zanoni M14 atomizer in spraying Foray 76B on a Sympatec Helos Vario KR particle size analyzer. The nozzle was tested at flight speeds of 140 and 160 mph (thus simulating an Air Tractor 502 and an Air Tractor 802) with different blade angles and different flow rates per atomizer. Each treatment lasted 5 seconds and was replicated three times. The lab simulated a temperature of 69.8°F and a relative humidity of 24.9%.

To define the flow rates per atomizer, we used the swath width recommended by Valent Biosciences in its "Foray Technical Manual" as a parameter, that is, a swath width of 175 feet (or 53 meters) for an Air Tractor 502 and a swath width of 200 feet ( or 60 meters) for an Air Tractor 802. To simulate an application from 1.37 L/ha to 1.47 L/Ha (approx. 0.146 GPA to 0.157 GPA), we used different flow rates per atomizer (such as if the AT802 was equipped with 4, 6, 8 or 10 atomizers and as if the AT502 was equipped with 4, 6 or 8 atomizers), according to the following table:

| Foray 76B Application: 1,37 L/ha to 1,47 L/Ha (approx. 0.146 gallon/acre to 0.157 gallon per acre) | ||||

| Hypothetical aircraft configuration: | Rate per atomizer: | Blade Angle | VMD | RS |

| AT 802 with 4 atomizers (160 mph, 200 ft) | 9.16 Liter/minute (or 2.42 GPM) | 55° | 82 μm | 1.3 |

| AT 802 with 6 atomizers (160 mph, 200 ft) | 6.02 Liter/minute (or 1.59 GPM) | 65° | 83 μm | 1.25 |

| AT 802 with 8 atomizers (160 mph, 200 ft) | 4.66 Liter/minute (or 1.23 GPM) | 65° | 82 μm | 1.25 |

| AT 802 with 10 atomizers (160 mph, 200 ft) | 3.52 Liter/minute (or 0.93 GPM) | 65° | 79 μm | 1.23 |

| AT 502 with 4 atomizers (140 mph, 175 ft) | 7.31 Liter/minute (or 1.93 GPM) | 55° | 89 μm | 1.32 |

| AT 502 with 6 atomizers (140 mph, 175 ft) | 4.66 Liter/minute (or 1.23 GPM) | 55° | 87 μm | 1.32 |

| AT 502 with 8 atomizers (140 mph, 175 ft) | 3.52 Liter/minute (or 0.93 GPM) | 65° | 85 μm | 1.3 |

In all those applications, the Zanoni M14 atomizer managed to offer the Volume Median Diameter (VMD) suggested by Valent Biosciences of around 80μm for the control of spruce budworm, with a very satisfactory droplet size uniformity (that is, with low relative span – RS, which indicates a low number of very small and a low number of very large drops, providing security in the application).

The Zanoni atomizer nozzle was also able to present other VMDs (bigger or smaller) according to the different blade angles, proving also to be suitable for applying Foray 76B to other types of pests, such as Gypsy Moth. In addition to testing in Nebraska, the Zanoni atomizer has already been certified to work in the province of Ontario, Canada.

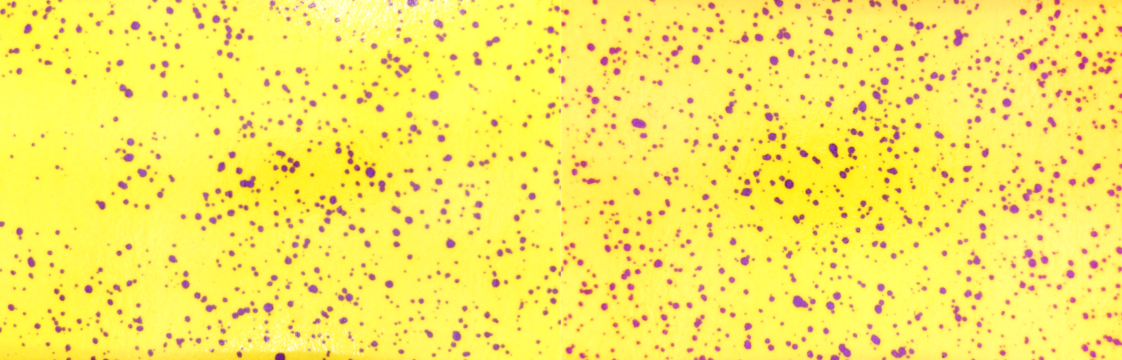

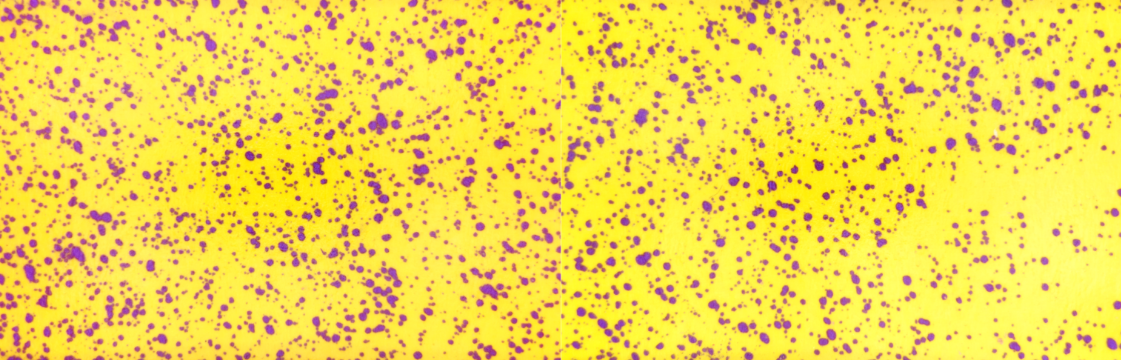

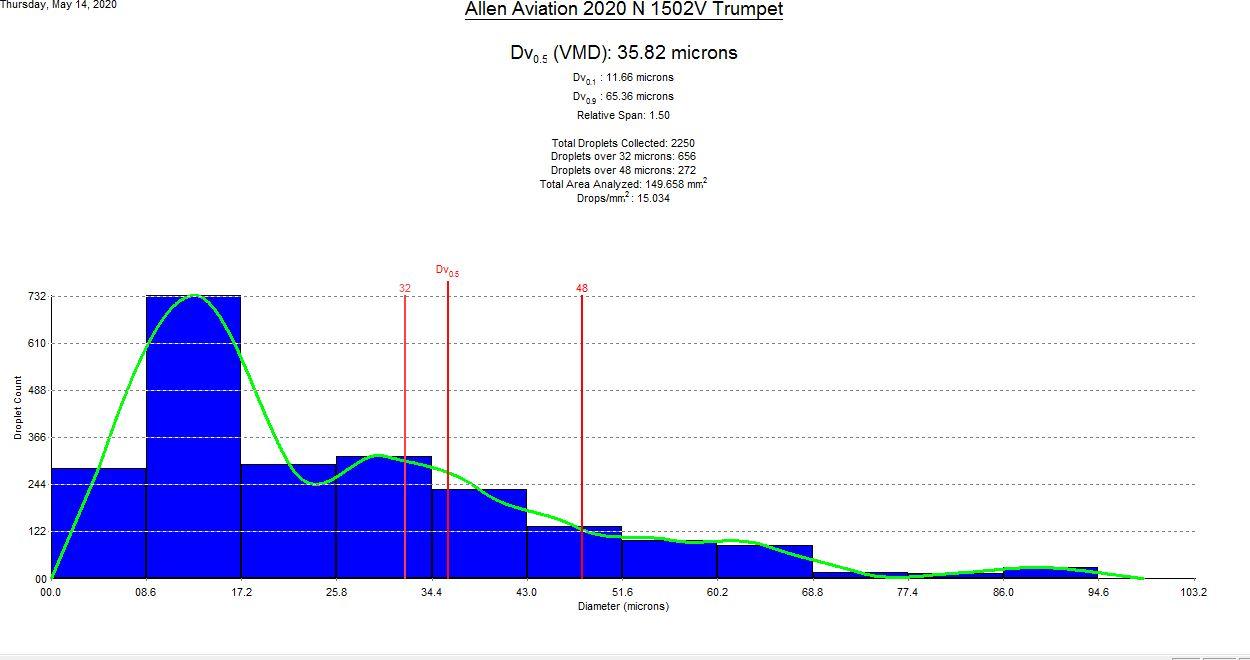

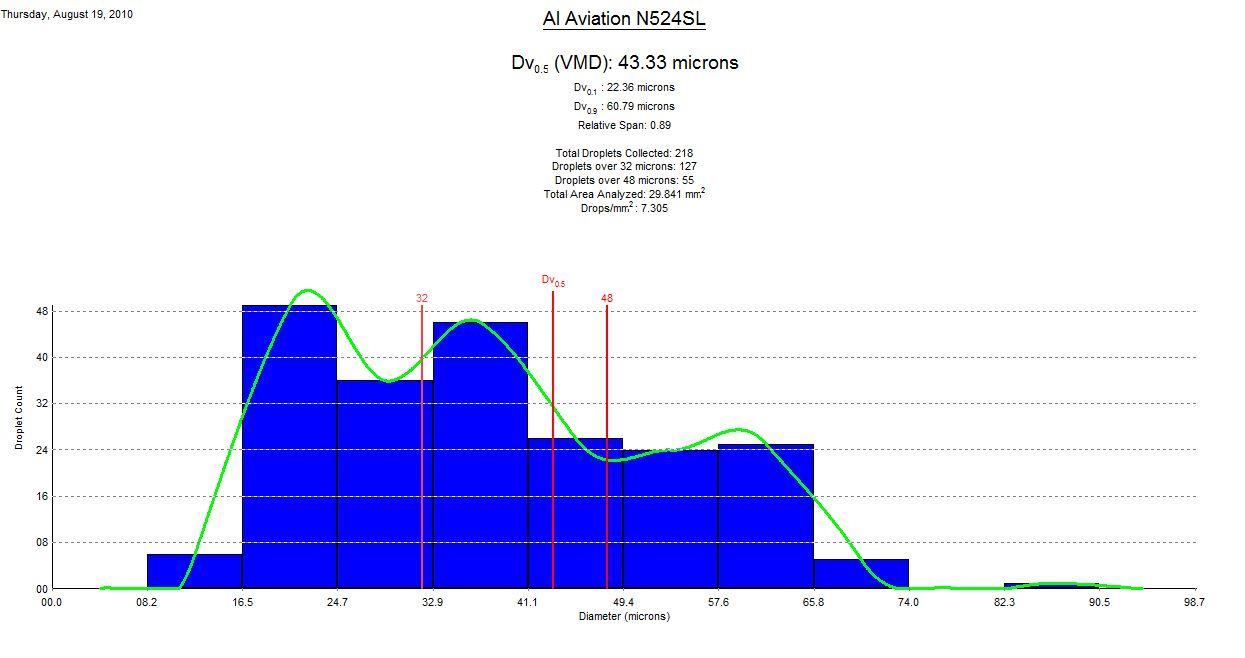

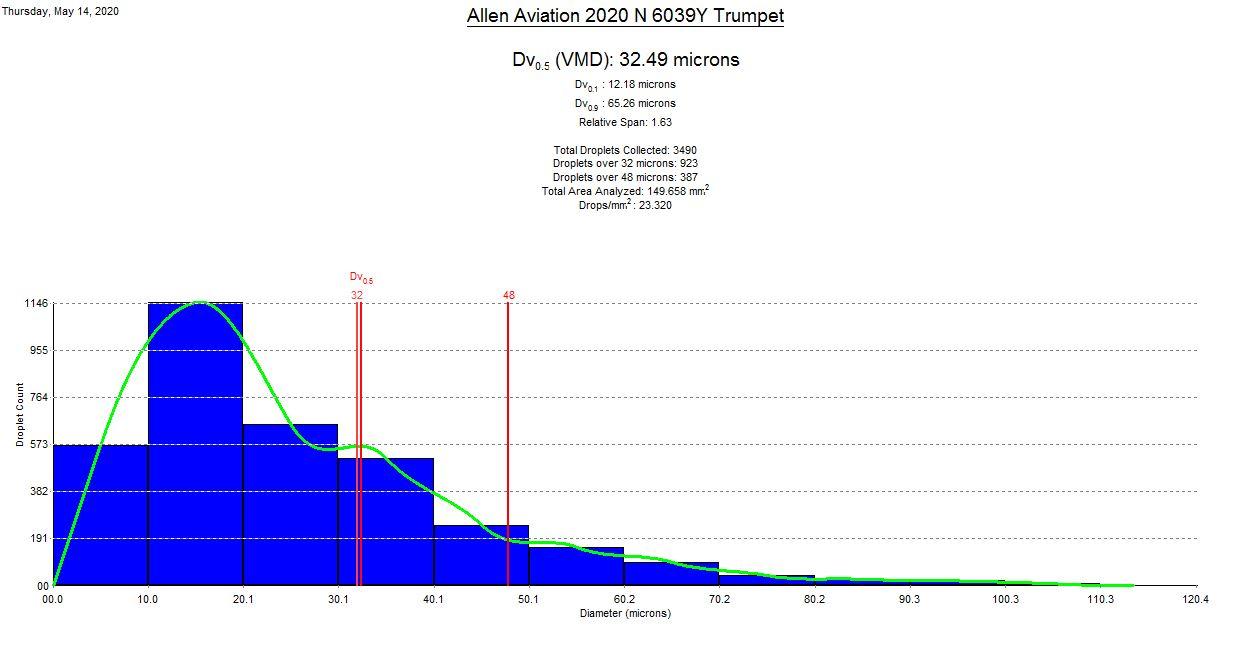

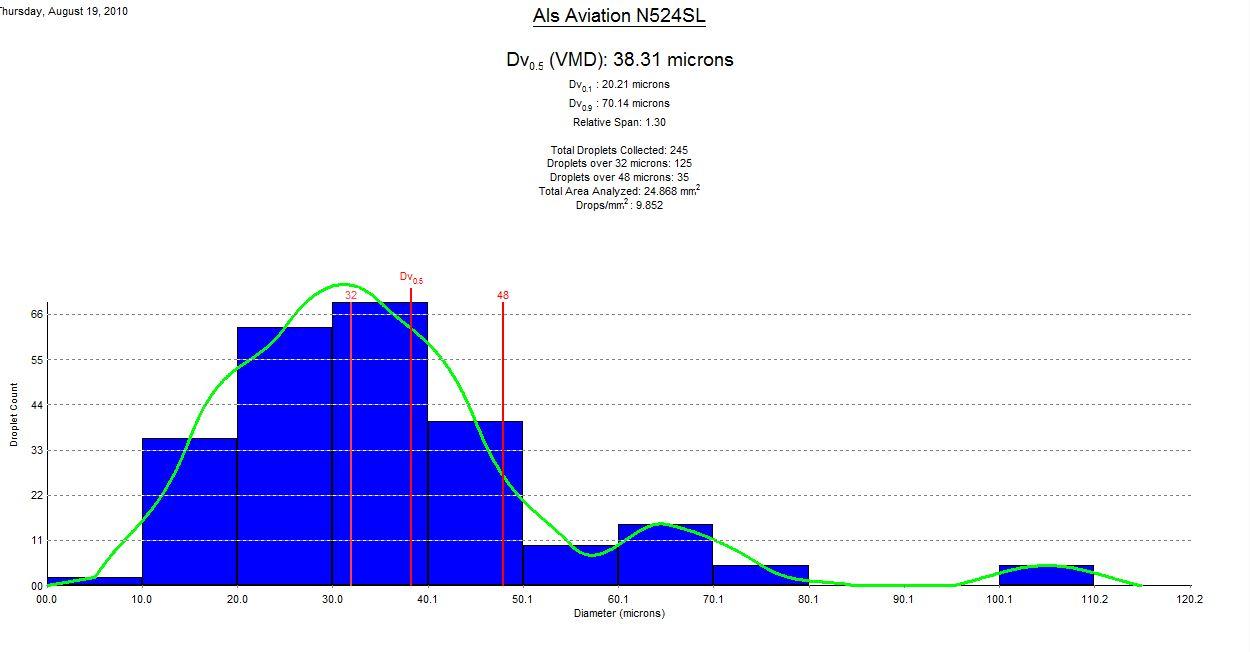

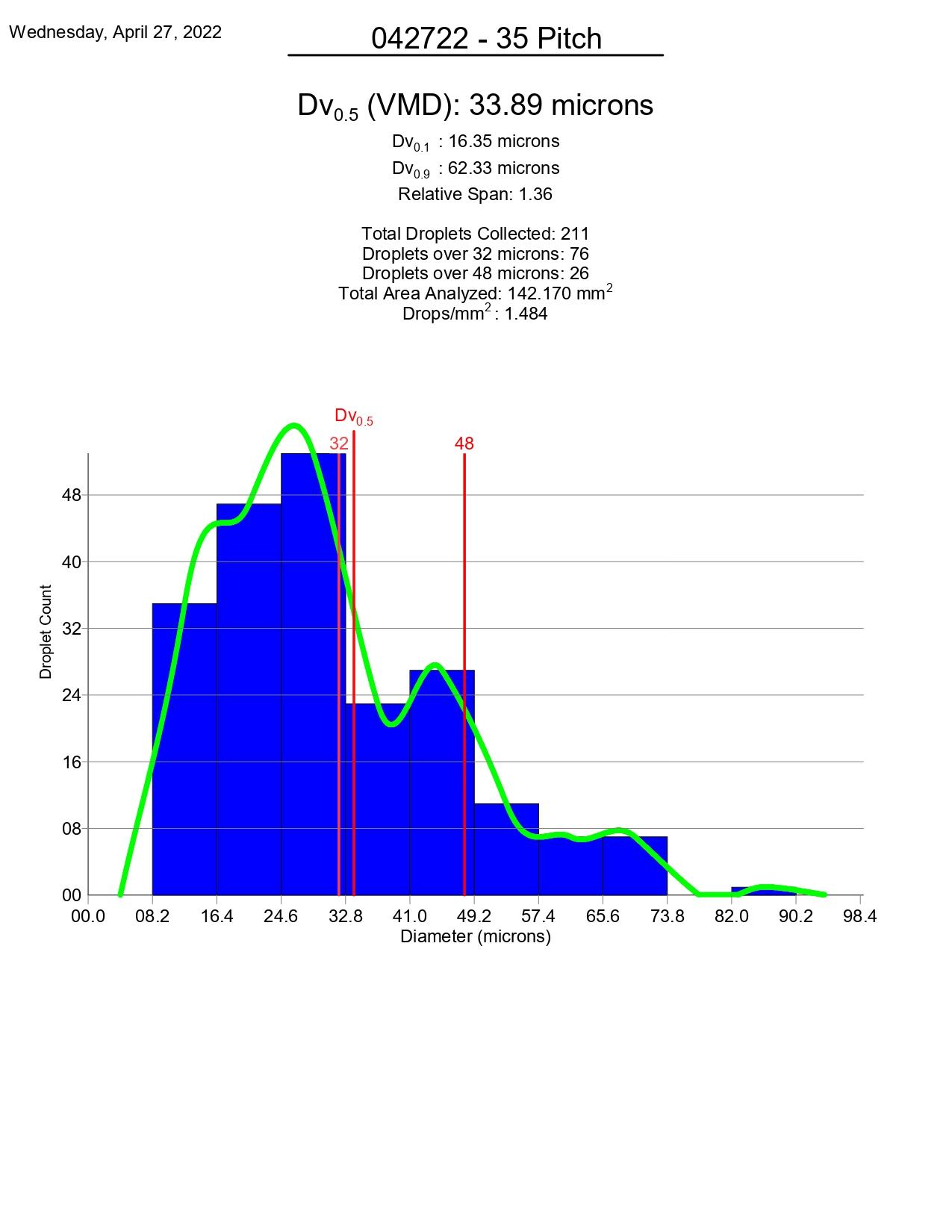

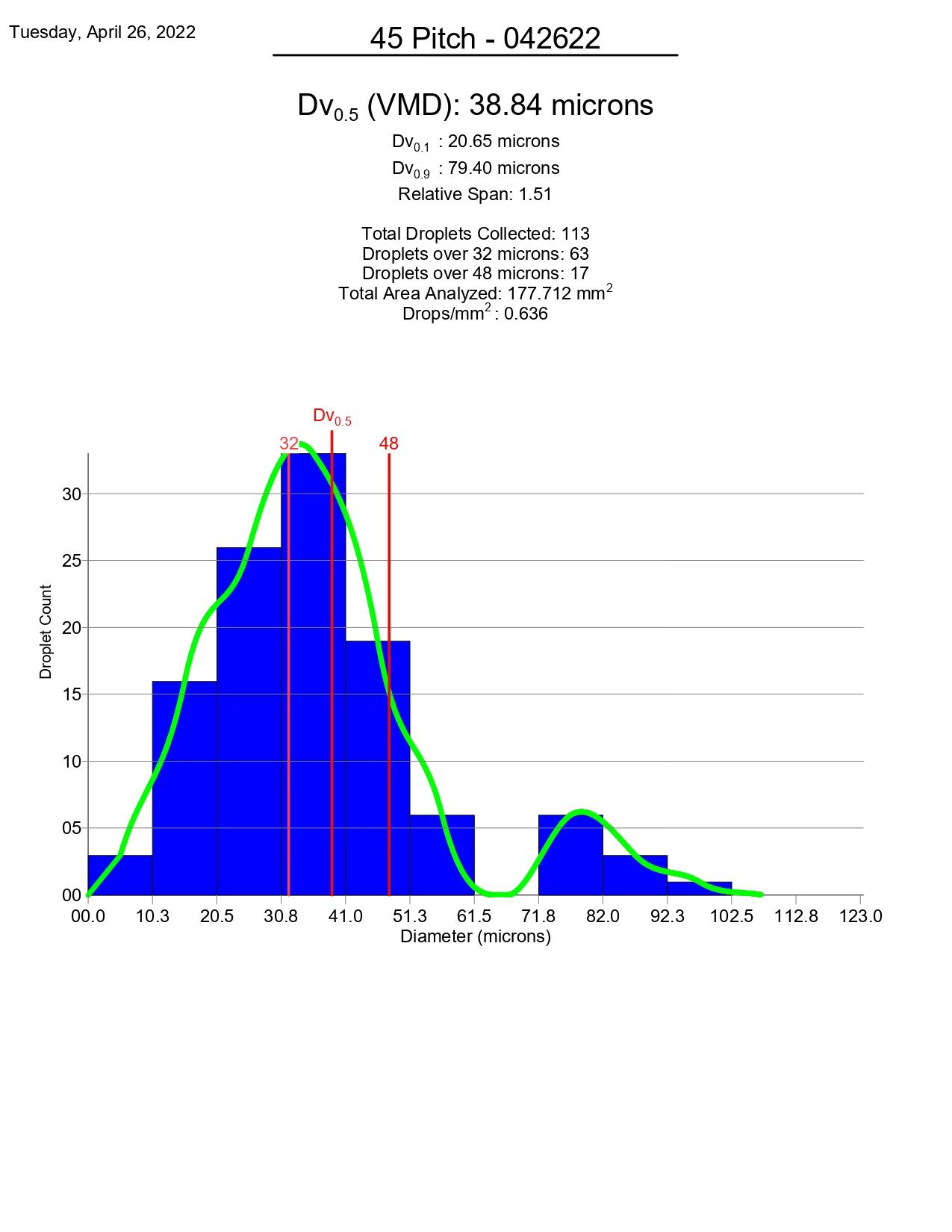

In addition to contributing to agriculture and forest protection, Zanoni rotary atomizers have also been used for mosquito control. Offering great results in the droplet spectrum for this job, the equipment has received excellent feedback from operators due to its great durability. As the nozzle needs to rotate far above normal operations, it is necessary superior durability to withstand this type of work. Below are the results of some research conducted with Zanoni atomizers on a Thrush aircraft, with the following parameters:

|

|

|

|

|

|

|

|

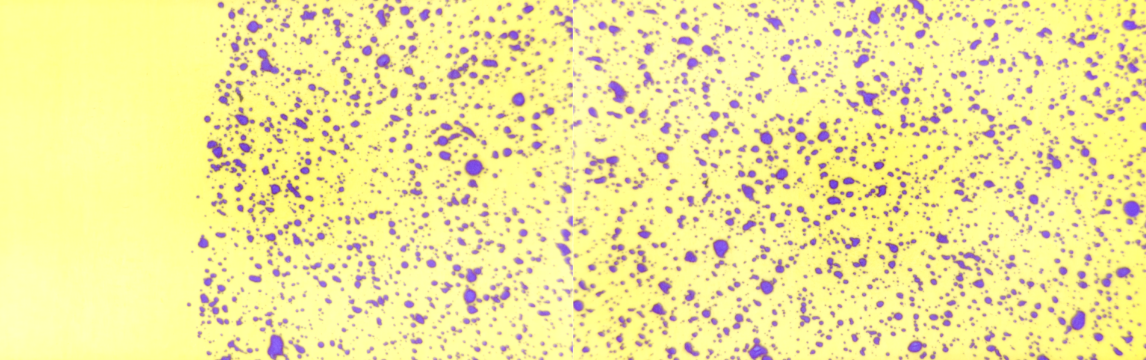

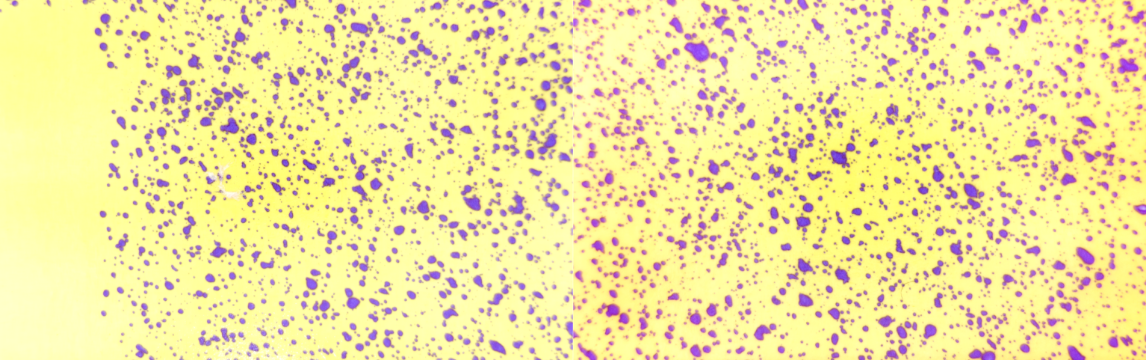

Our atomizers have also shown great results in twin-engine aircraft. Held in the state of Utah in April 2022, an aircraft clinic evaluated the droplet spectrum of Zanoni atomizers on a Navajo Chieftain and a Piper Aztec. The calibration trials with the Zanoni M14 Rotary atomizers showed that they were able to meet label requirements for adult mosquito control operations (Dv0.5 <60μm, and DV0.9 <115μm). One of the greatest specialist in mosquito control in the US gave us her impressions on the results, “This is the droplet spectrum pattern we need for mosquito control. Very small droplets, to ensure there is a large number of them in the target (i.e. a large density). This is how we manage to kill the mosquitos and ensure a safe and sound aerial application”.

|

|

Zanoni Equipamentos © 2025 - All rights reserved