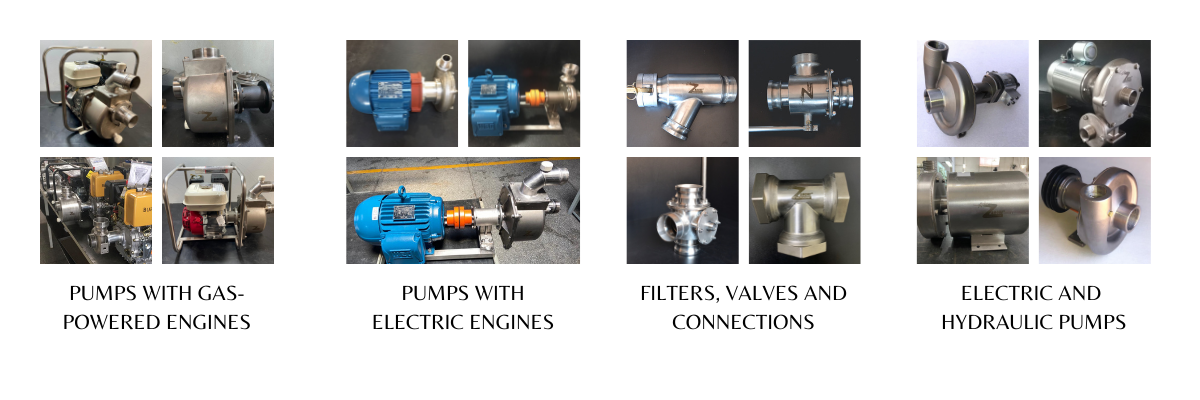

Zanoni Equipamentos started the production of equipment for transferring corrosive liquids as a way to help our ag aviation partners, who demanded more resistant products than those traditionally available on the market.

| One of the greatest contributions of Zanoni Equipamentos to ag aviation was the introduction of the use of stainless steel. With a resistance to corrosion of agrochemicals far superior to other conventional materials, stainless steel adds value to the operator, since the products have a longer useful life and this reduces maintenance headaches that hinder work in the field. There are Zanoni spraying equipment that has been in operation for more than 20 consecutive crop seasons. |

THE STRENGTH OF STAINLESS STEEL:

|

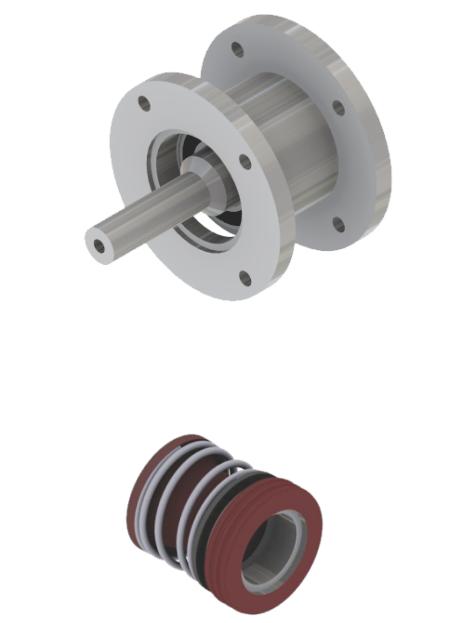

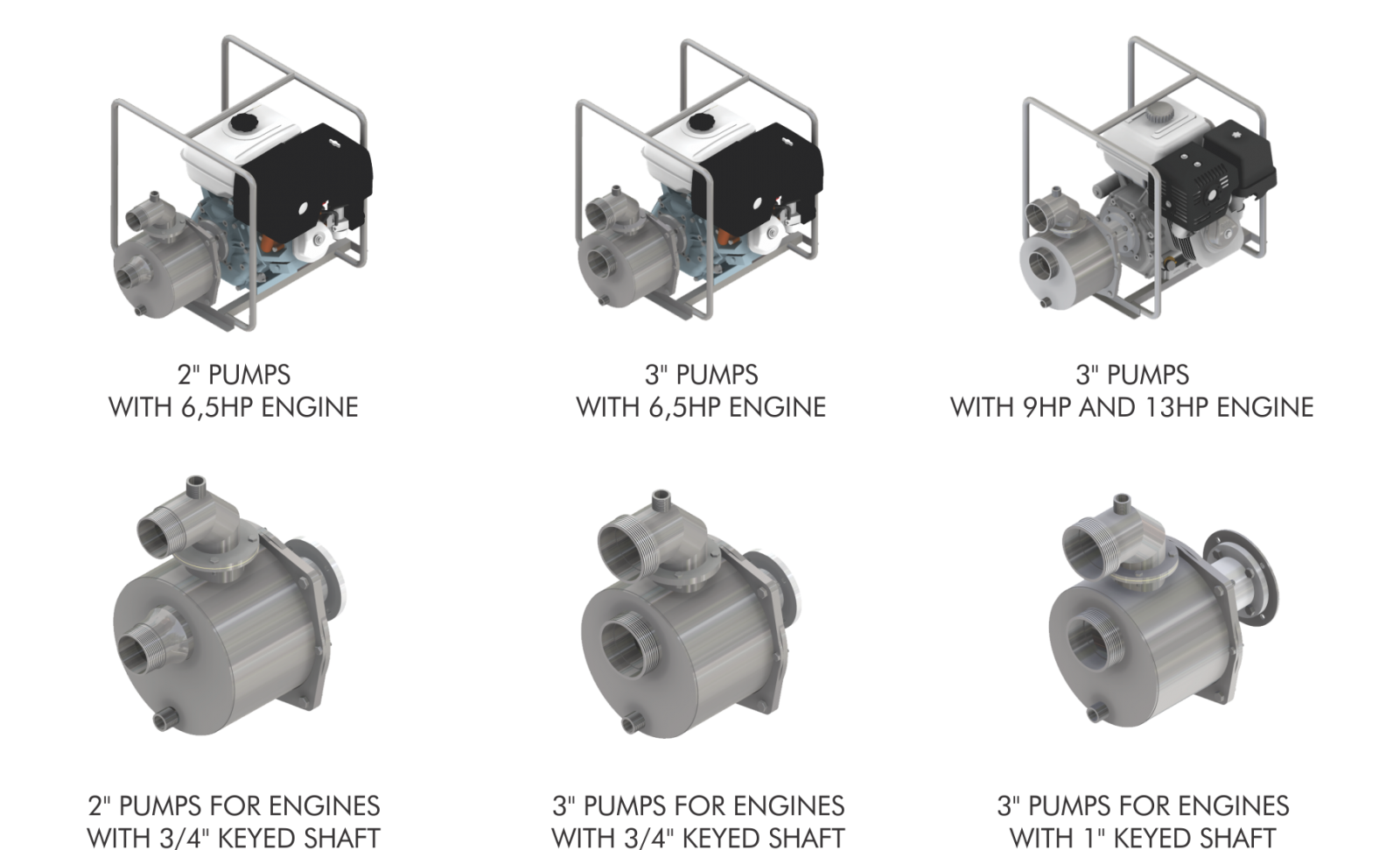

Zanoni gas-powered pumps are equipment designed to handle corrosive liquids, installed in several kinds of engines, such as Honda (GX Series), Buffalo and Branco. They are mainly indicated for use in mobile bases, when it is necessary to constantly transport the equipment between different places (for fixed bases, we recommend the use of pumps with electric motors, presented below). The Zanoni pumps have a 100% stainless steel structure, including its high-performance impeller. In addition to stainless steel, we brought three other innovations in this line of equipment:

|

|

|

Zanoni Equipamentos offers two main models of pumps for gas-powered engines (for those with 3/4" shaft and for those with 1" shaft), in addition to offering some options already with the engine installed directly from our factory (Honda, Buffalo and Branco). The 2" pumps achieve flow rates of up to 750 liters per minute and the 3" pumps offer different flow rates according to engine power (for example, with a 9HP Honda engine, it offers flow rates of up to 1300 liters per minute). Consult the Zanoni team to assess which engines are adaptable to our pumps. For more information about the different models, click here. |

|

|

Due to the long service life of our products, Zanoni pumps are now supplied to some of the largest Brazilian manufacturers of agricultural spraying equipment. The corrosion resistance offered by stainless steel and the other technologies used by Zanoni are ideal for the work of handling corrosive liquids. Zanoni pumps are installed in equipment such as chemical inductors, pre-mix and water tanks, supply trucks, among other lines of implements that need reliability and do not let the operator down with constant maintenance during the spray season. If you are interested in developing a new project for your company (either for field operation or for equipment manufacturing), please do not hesitate to contact our team. We are always open doors to find solutions for our partners. |

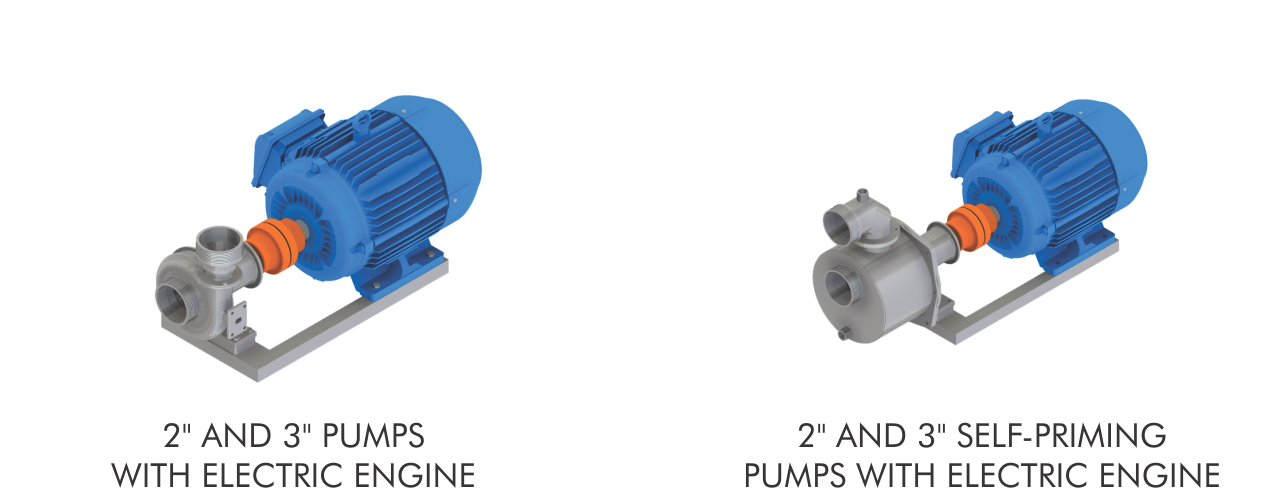

Zanoni electric-powered pumps are also equipment designed for handling corrosive liquids. For use on fixed bases (when it is not necessary to move the equipment), its differential is in the silent engine with easy operation (much simpler than in gas-powered engines), in addition to having a longer service life and being more economical. Three-phase and 220V voltage, the engine can work continuously without problems.

| Zanoni pumps for electric engines are manufactured in 2" and 3" with different power (7.5CV, 10CV and 15CV), in self-priming and "conventional" options. The equipment has the same characteristics as the Zanoni gas-powered pumps, to ensure great durability (100% stainless steel structure, tungsten and silicon carbide seal, and bearing housing). |  |

Due to the superiority of stainless steel over other materials, both in terms of corrosion and impacts, we also started to manufacture some components to assist in the handling of agrochemicals, such as line filters, directional valves, couplings and connections.

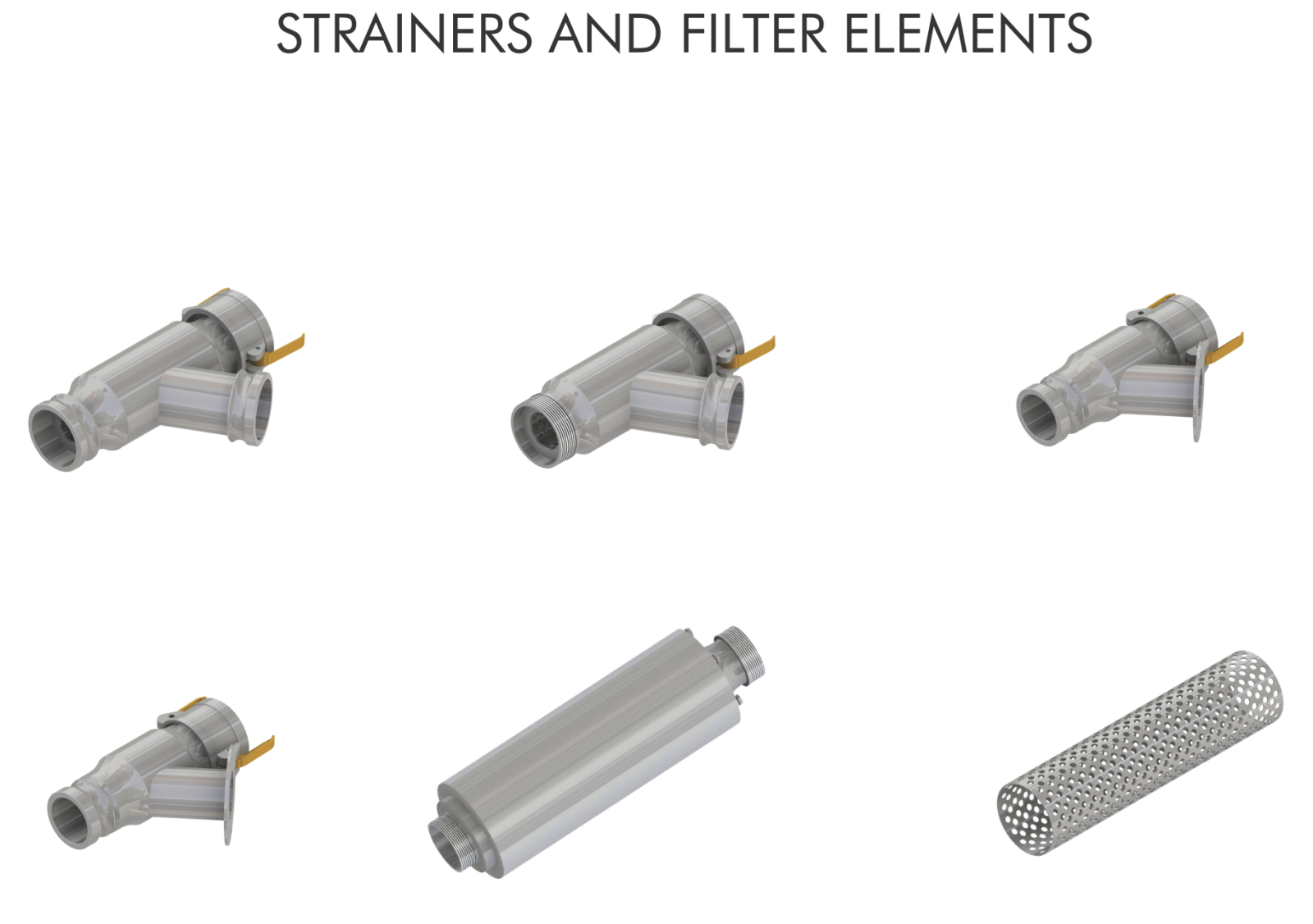

FiltersZanoni filters are manufactured in different formats to adapt to different systems. We have models with quick coupling, threaded inlet and outlet, tube for hose and flanges, in dimensions of 1 1/4", 2" and 3". The elements are also manufactured in stainless steel, with meshes of different sizes, offering versatility for filtering different types of products. |

|

|

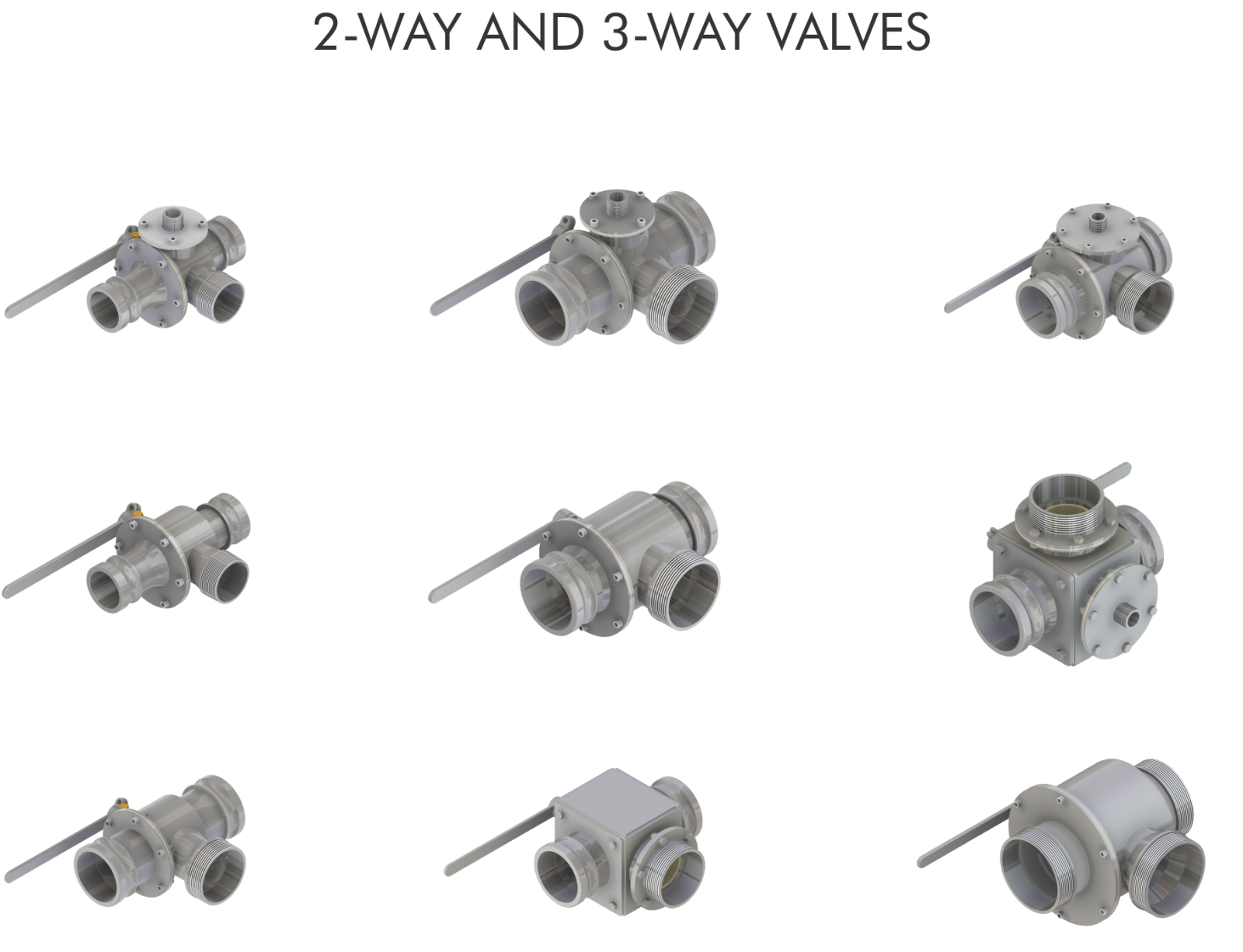

Directional valvesZanoni directional valves are also manufactured in different models. We offer two-way and three-way options, with dimensions of 2", 3" and 4". The three-inch valves have different versions, with lighter and more robust options. In addition to the durability of stainless steel, the equipment has a very high quality finish (with an global recognized weld) and easy maintenance. |

|

|

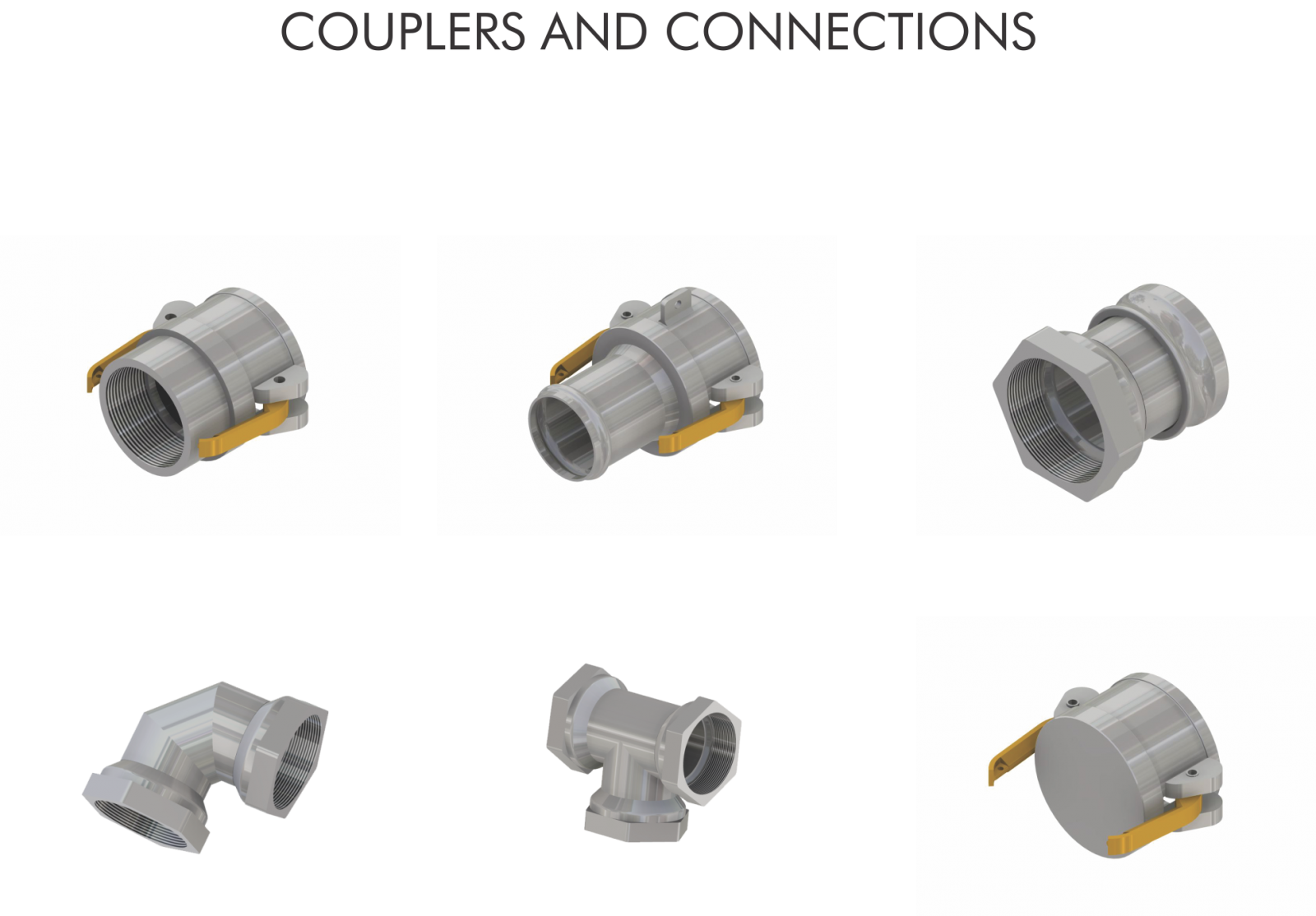

Couplings and connectionsZanoni also manufactures 3" stainless steel fittings (tee and elbow) and 1 1/2", 2" and 3" couplings of the following types:

|

|

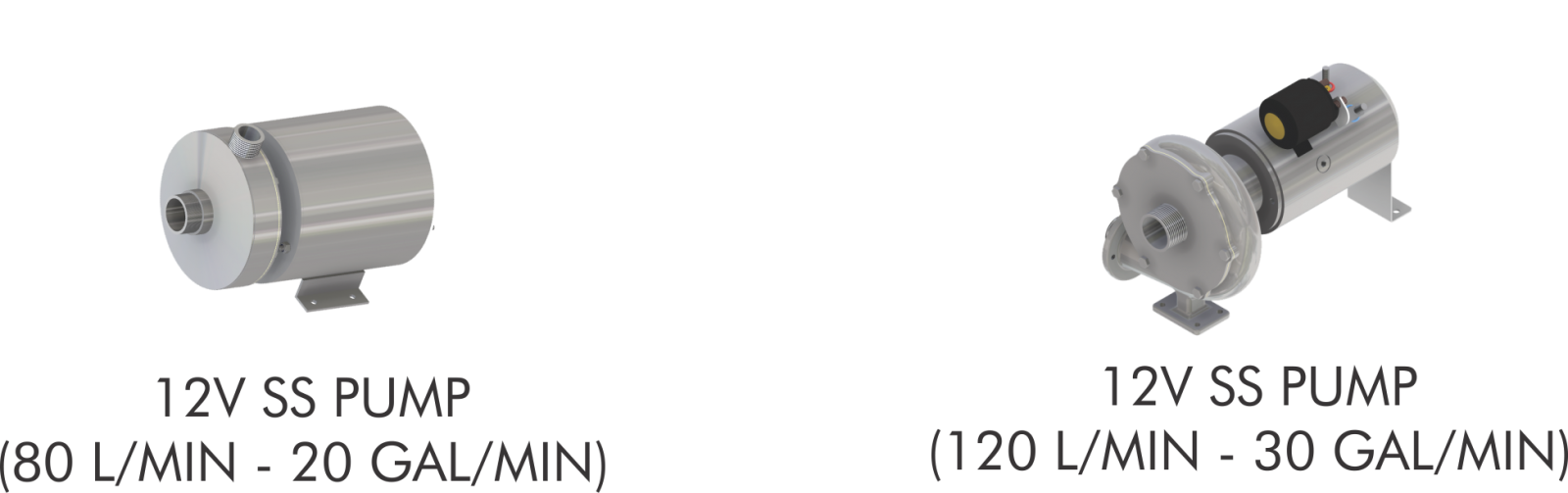

Another product line developed by Zanoni to deal with corrosive liquids are our centrifugal pumps (electrical or hydraulic).

| Zanoni electric pumps are designed to be connected to 12V batteries. In two versions (one with a flow rate of up to 80L/min and the other with a flow rate of up to 120L/min), they are recommended for short-term work (maximum 5 minutes). |  |

|

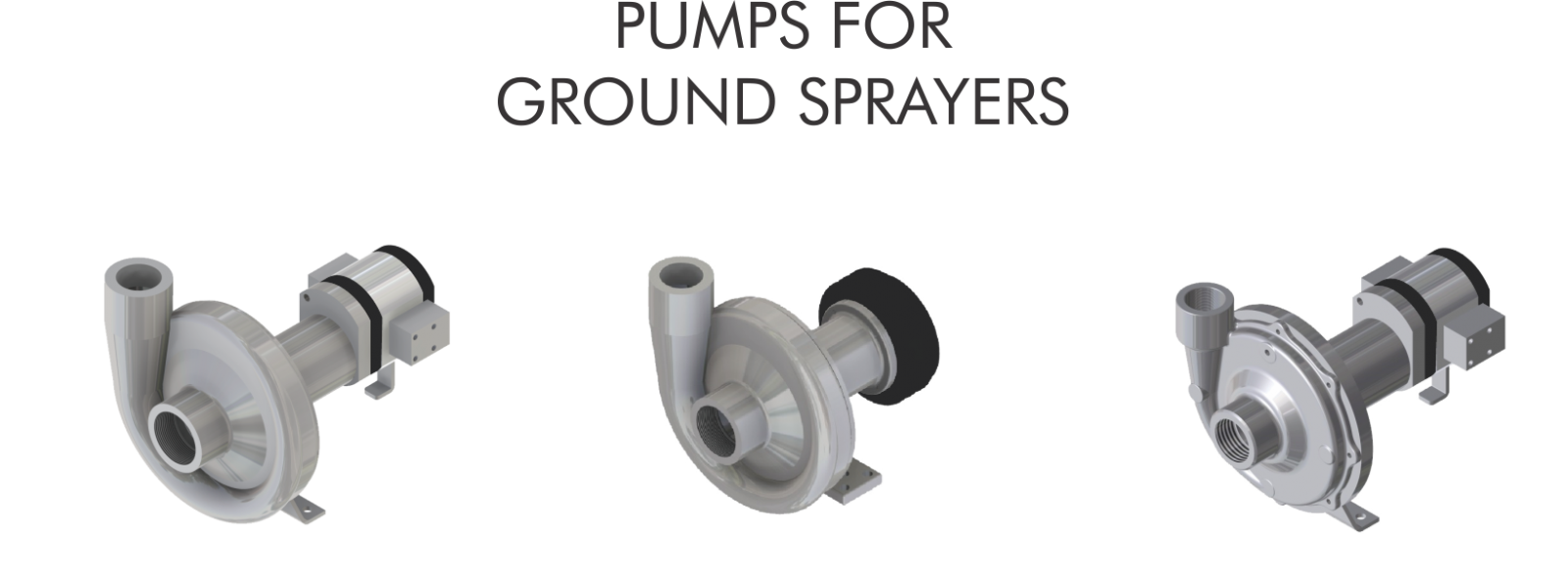

| At the request of some agricultural aviation partners who have self-propelled sprayers, we have also developed some centrifugal pumps for ground spraying. We have hydraulic pump models for Metalfor, John Deere, Stara, Massey and Valtra. |  |

Zanoni Equipamentos © 2025 - All rights reserved